|

| November 05, 2019 | Volume 15 Issue 42 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Drill, grind, polish, and cut with these heavy-duty robot tools from SUHNER

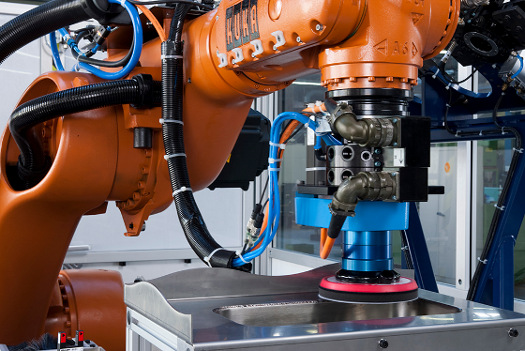

Standardized connections at the robot arm and the tool are used to automate SUHNER's quick-change system, which is particularly useful when using abrasives.

New end-of-arm tooling solutions from SUHNER's ROBO Tools line can help you handle those heavy-duty tasks. Ever since it was founded, SUHNER has been working on low-cost automation and is regarded today as a go-to specialist in machining units for drilling, milling, and thread-cutting operations. Their products come with built-in flexibility, because they can be put together in a modular system that can be tailor-made for your project.

VIDEO: See SUHNER Robot Tools in action.

For stationary machining applications, SUHNER products already represent a first choice for many companies. In cases where the cutting tool must be moved toward the work piece, there are many practical solutions -- but many prove insufficient in a heavy-duty environment. This gap is now being closed by the SUHNER robot machine tool program. One option is to bring the work piece toward a standard stationary SUHNER machining unit. Today, SUHNER offers the possibility to adapt and guide the tool by the robot.

As a specialist in automation processes, machining units, handheld power tools, and abrasives, SUHNER has expanded its wide product range with special tools that can be mounted directly to the robot arm for continuous industrial use. One new capability of the robot tools is surface finishing. The application range is enormous.

Air spindles are adapted for precision works like deburring, finishing, and many other uses.

Quick-change systems

Standardized connections at the robot arm and the tool are used to automate the quick-change system. Connections are made quickly and reliably between air and electrical and sensor technology.

One of the key requirements for quick-connecting components is to apply proven technology with a high degree of interchange reliability. Components from SUHNER meet this requirement.

Changing abrasives

Abrasives typically have a short life cycle. A patented and simple quick-change abrasives system (dispose and reload) has been added to SUHNER's offerings. This system allows the use of different abrasives in sequence to achieve a desired surface finish. An automated abrasive change increases flexibility and eliminates unproductive production hours.

Some SUHNER robot tools include both manual and automated quick-change options.

Servo motor-driven angle grinders

Today, most robot guided grinding and polishing machine tools are operated by air. Often, considering a 24-hour operating environment, these machines are pushed to their limits. Frequent service interruptions, plus extremely high air consumption, add to energy costs -- which can also affect profitability.

In addition, air-driven tools drop in speed when under load, which can contribute to an adverse effect on the surface finish. Depending on surface quality requirements, the rotation of the grinding or polishing tool often requires both clockwise and counter-clockwise rotation, which an air-driven tool can't accomplish.

Robot tools like this angle grinder and orbital sander have been developed to handle high speeds in continuous operation.

Want to learn more? Go to https://spindles.suhner-machining.com/en/products/robotmaster/.

NOTE: If the SUHNER website takes you to the home page, choose: Products > ROBOTmaster from the menu at the top left of the page (three vertical lines).

Or contact Lee Coleman, SUHNER, directly at 706-235-8046. Lee will be happy to answer your questions.

Source: SUHNER

Published November 2019

Rate this article

View our terms of use and privacy policy